Rotomoulding: from design to market

Rotomoulding, or rotational moulding, is a versatile process offering significant design flexibility and a low start up cost. It has many benefits over other plastic moulding processes and is cost-effective and more environmentally friendly.

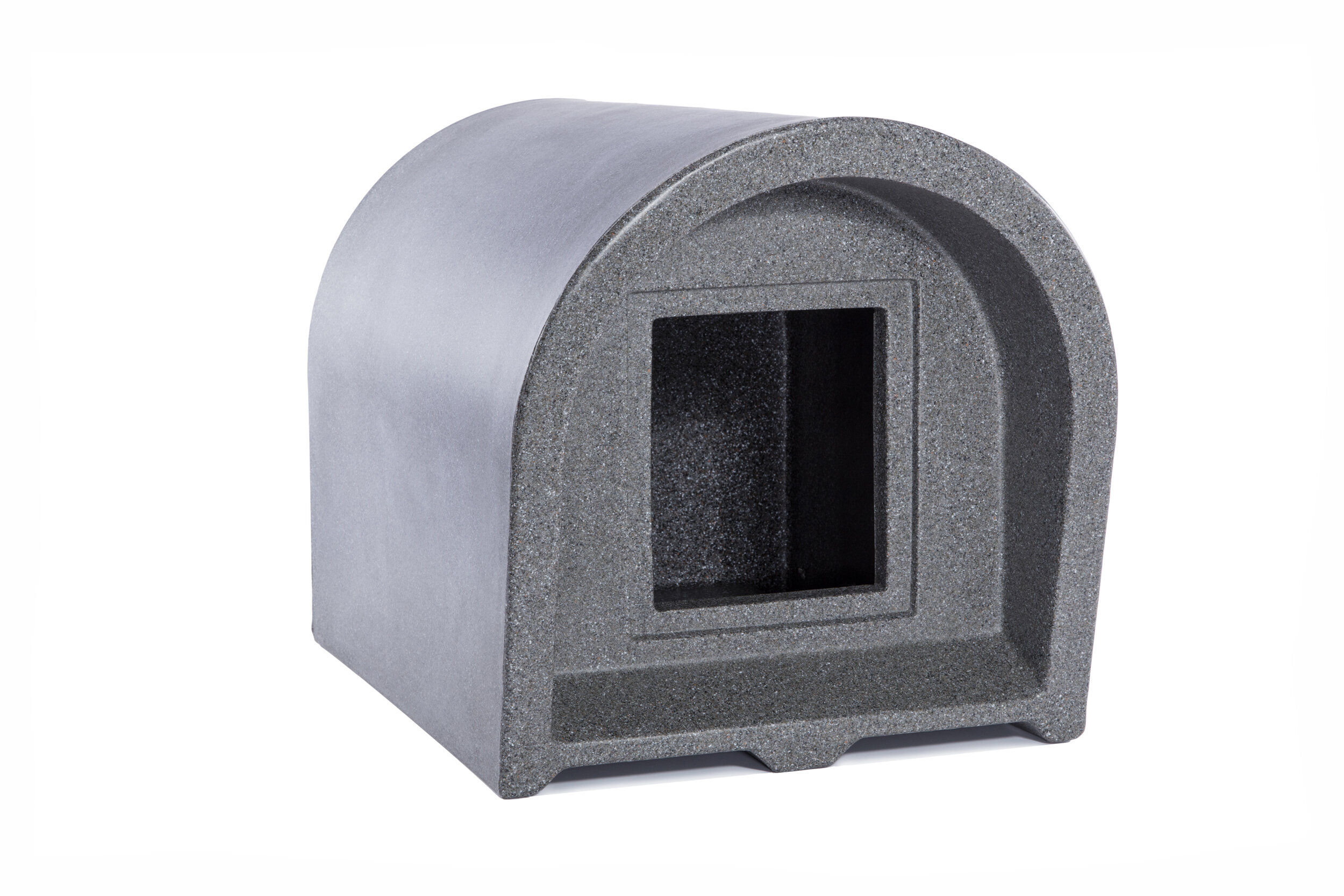

The process is ideal for making complex medium to large parts with intricate features such as moulded in handles, graphics, threads and inserts. There is almost no limit to the size of the mouldings which can be used for a diverse range of products. These include body parts for cars; surfboards; playground equipment; manhole covers; water filtration devices and commercial cleaning equipment.

Pros of rotomoulding

Because there is little pressure in the process the tooling can be made from low-cost metals such as steel.

There are no size limitations.

The low stress process protects the material from cracking.

The wall thickness is uniform and the double wall construction can be produced without secondary processing.

Waste is minimal as it can be recycled.

The end products are exceptionally durable with no weak points.

Cons

The raw materials need to be easily converted into a fine powder and must have high thermal stability. This limits them to poly-based resins which can be high cost.

The process is more labour intensive than comparable manufacturing processes.

At eight rotations a minute, rotomoulding can take an hour or more to complete one part. But this can be overcome with multiple low cost tools.

The soft metal used in rotomould tooling needs to be replaced/refurbished after several thousand cycles.

So how is rotomoulding done?

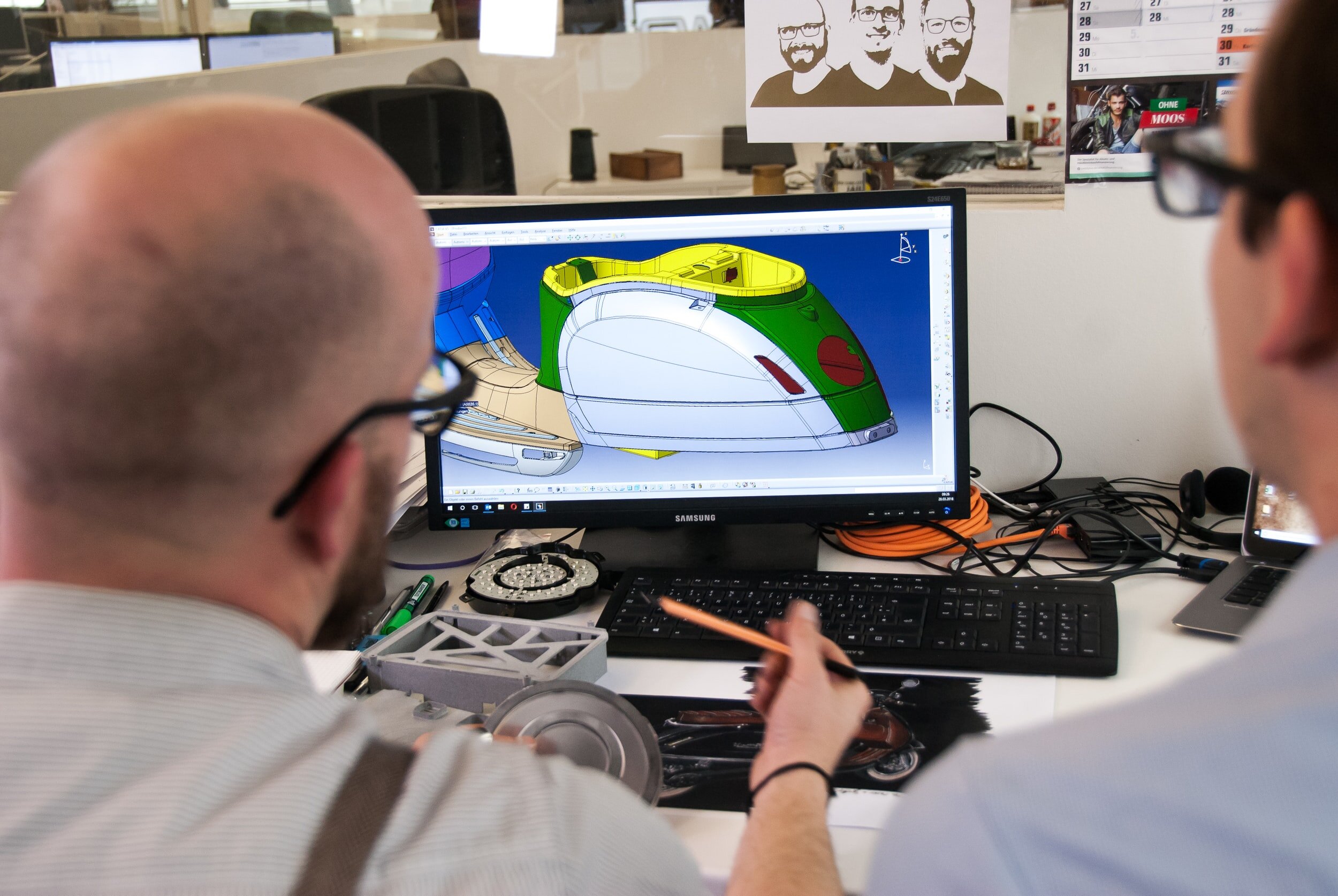

When the need for a product is identified customers can either get the design drawn up by an in-house team, if they are a large company, or approach a rotational moulding company and use their expertise and support to help design a prototype.

Customised design can include product assembly, the addition of graphics, welding, inserts as well as packaging and shipping.

But first of all, to ensure the product is going to do the job it is intended for, it is necessary to determine exactly what function it will have and the environment it will operate in.

A number of factors need to be taken into account during the design process. If the design is not created with the rotational process in mind some areas can be difficult to mould. Other considerations include wall thickness and separation - any parts with undercuts need to be designed with product removal in mind.

It is also worth considering how the mould will open and close around the product - the most cost-effective and least maintenance mould has two pieces. Because the product is created on a hollow mould, with no internal cores, flat walls can be difficult to produce. They are susceptible to warping. Designs can avoid flat walls by adding in reinforcement ribs or a crown. But generally they are not recommended.

Also to be avoided are sharp corners which can create stress in the finished item. And bear in mind, due to gasses that are expelled when the resin cures, a vent hole is required in all tools. The size of the vent depends on the volume of the cavity and for larger, more complex products, several vents may be needed.

Once the design is agreed the tools are made. Tooling can be made from sheet steel, cast aluminium or CNC aluminium. The most common type of tooling is cast tooling which offers a wide range of options for surface finishes and textures. The precision of the rotomoulded part is key to the quality of the end product.

The process

Rotomoulding is a unique process which uses heat to melt and mould plastic resin in a closed mould.

Polyethylene (plastic) powder and a powdered colourant, are added to a hollow mould tool made from either sheet steel, cast aluminium or CNC aluminium. The mould/tool is clamped shut and heated up to between 220C and 350C. The tool rotates at a low, even speed and, as it heats up, the powder melts in thin layers of even thickness, regardless of whether the mould has corners, and sticks to its inner surface until it has completely melted. Some products have metal components moulded in.

The moulded product is then cooled before being removed from the tool leaving behind no waste material. The result is a hollow, virtually seam-free shape with a consistent and even wall thickness.

The product can then be precision cut before being assembled and hand-finished ready for delivery to the customer.

What’s the alternative?

If rotomoulding is not right for your product there are alternatives.

The injection moulding process could be used for solid objects such as caps, switches and medical devices. Here the material is melted and quickly forced into a stationary mould under high pressure which distributes the material throughout the mould. This process can be used for highly complex moulds and a wider range of more cost-effective materials can be used. It can offer a faster turnaround on the production line so reducing costs.

But there are disadvantages. You can’t achieve a consistent wall thickness with injection moulding, the corners will be thinner (in rotomoulding they are thicker) so more vulnerable to damage and the process has a high cost of entry.

Blow moulding could also be considered - this works like traditional glassblowing. Heated plastic is air blown into a mould cavity like a liquid balloon to create a hollow thin-walled object. The air forces the heated plastic to expand across the interior walls of the mould cavity. This method has shorter cycle times for parts with more limited design flexibility. Initial start up costs can be significantly higher than those of rotational moulding tooling. The final finish is not as polished as that produced in rotomoulding. It is often used to produce bottles, plastic drums, traffic cones and watering cans.

Extrusion moulding is when hot melted plastic is pressed through a shaped hole to create a lengthy shaped plastic part. This is best used on hoses, pipes, gutters and decking. Although low cost, it is very limited as to what it can be used for.

Compression moulding is when liquid plastic or rubber is simultaneously heated and then compressed to create a shape. This is best used for small parts such as o-rings and gaskets. This can be very low cost when in mass production.

We hope this helps you to determine what kind of process would best suit your product idea but please get in touch and have a chat with one of our experienced team and we’ll be happy to advise.